1872

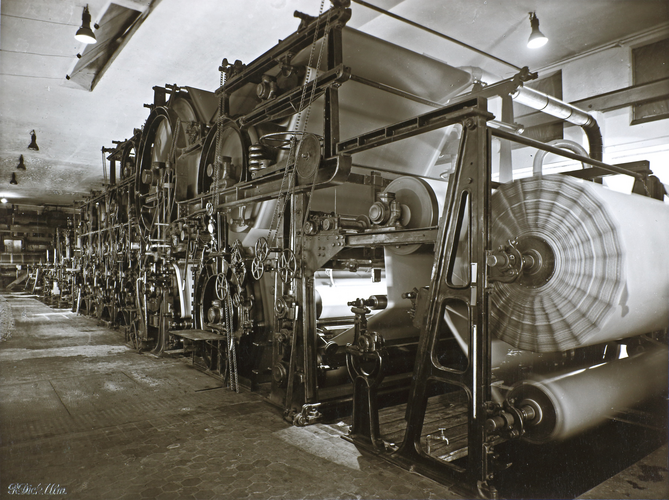

At the age of 26, the merchant Adolf Palm acquired a water-powered factory in Neukochen, Germany, to manufacture agricultural iron products. He very quickly converted the production line to produce paper made from secondary fibres; this was an early form of recycling. Adolf Palm discovered a base material, which already the ancient Chinese had used to make paper - bast fibre. The material could be acquired cheaply due to the residue from the local textile industry. Using the motto "excellent and tough natural brown bast paper" to advertise its packaging material, the company manufactured a very innovative and competitive product.

1876

The annual production rate is 220 tonnes.

1918

Adolf Palm hands over the running of the company to both his sons, Otto and Hermann Palm. The annual production rate is 1,500 tonnes.

1921

Purchase of a new paper machine made by Voith in Heidenheim.

1952

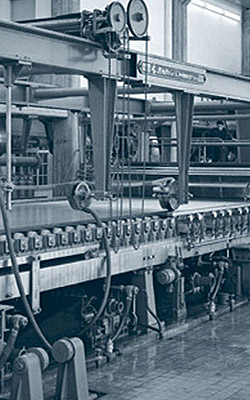

Dr. Wilfried Palm, the son of Otto Palm, and the Engineer Gottfried Palm, the son of Hermann Palm, joined the management. The annual production rate exceeds 10,000 tonnes.

1956

A second Voith paper machine went into operation.

1962

The third paper machine at Palm is the first German machine for corrugated base paper with a dual web width.

1968

The first Testliner paper machine in Germany went into operation.

1974

The fifth paper machine, the world's fastest cylinder mould former machine, went into operation.

1979

With the acquisition of both, the corrugated board plant in Bruchsal, Germany, and the paper mill in Malsch, Germany, for the first time Palm enters the manufacturing arena for corrugated board.

1981

The plant for collapsible boxes was constructed in Neuthard, Germany.

1982

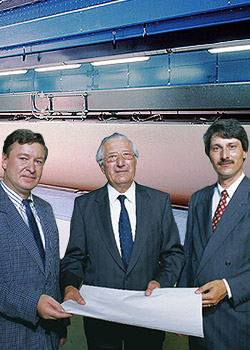

Dr. Wolfgang Palm, the son of Dr. Wilfried Palm, joins the management; this is now the fourth generation entering the family business.

1983

A paper machine for graphic paper started up.

1984

Palm is the first German paper mill to successfully produce newsprint paper made from 100% recycled paper.

Acquisition of the corrugated board plant in Sinsheim, Germany.

1986

Acquisition of three corrugated board plants in Forchheim, Gelsenkirchen and Höchstädt (all situated in Germany) from the Vereinigte Papierwerke Schickedanz.

1989

The annual production rate in Neukochen, Germany, exceeds 240,000 tonnes.

1994

Construction of the paper mill in Eltmann near Bamberg, Germany, and installation of PM1. With this high-performance paper machine the production capacity for newsprint paper was tripled.

1997

Acquisition of the corrugated board plant in Alzenau, Germany.

Acquisition of the processing plant in Germersheim, Germany.

1998

Acquisition of the corrugated board plant Nestler Wellpappe in Lahr, Germany.

Acquisition of two BECO Wellpappenwerke in Hasselroth and Andernach, both in Germany.

1999

Expansion of the plant in Eltmann, Germany, and installation of another paper machine, PM 3, producing

newsprint.

2000

Acquisition of the processing plant WellPack in Einsiedeln, Switzerland.

2001

Acquisition of the corrugated board plant PilloPak in Eerbeek, the Netherlands.

Acquisition of the processing plant Brenner in Starnberg, Germany.

2002

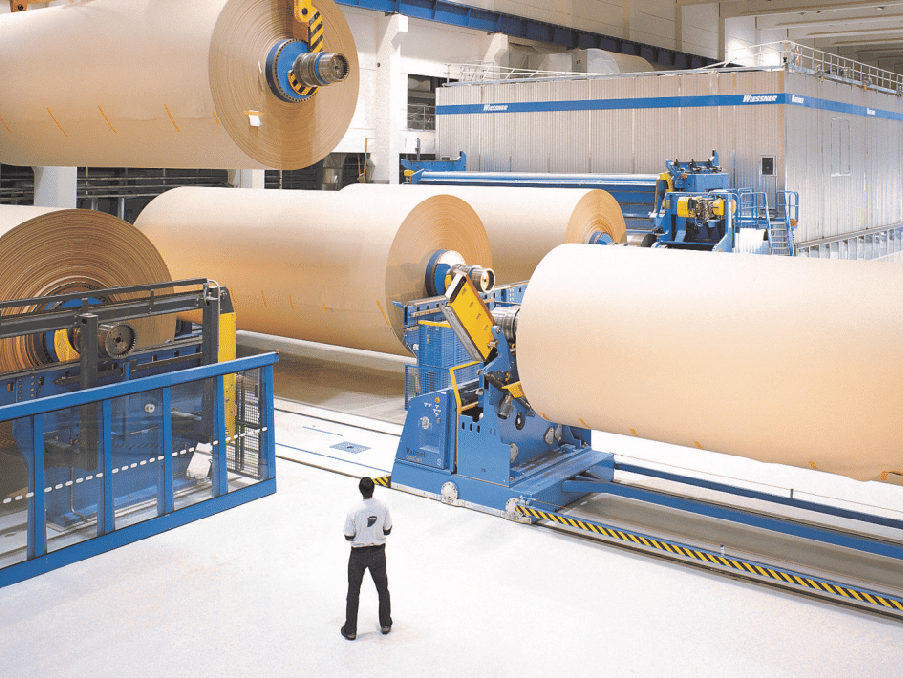

In Wörth, near Karlsruhe in Germany, another paper mill was constructed by Palm on a large industrial site with good links to the railways, the motorway and a port to the river Rhine. Palm put the world's largest paper machine into operation with an annual capacity of 650,000 tonnes of corrugated case materials.

2007

The corrugated board centre in Wörth am Rhein, Germany, went into operation.

Acquisition of the corrugated board plant Packwell in Schwepnitz, Germany.

2008

Acquisition of the processing plant Drupack in Villingen-Schwenningen, Germany.

Acquisition of the corrugated board plant Emil Stahl in Fürth, Germany.

2009

The world's largest paper machine for newsprint went into operation in King's Lynn, Great Britain (90 miles northeast of London). The annual capacity is 400,000 tonnes with a working width of 10.63m and a production speed of 2,000m/min.

2010

Palm Recycling was established in the UK.

2013

Introduction of Palm Recycling in Aalen-Neukochen, Germany.

2014

Acquisition of the Seyfert Group together with the Descartes paper mill and 5 corrugated board plants in France plus 3 corrugated board plants in Germany.

2016

Acquisition of the Corrugated Board Plant in Zorbau, near Leipzig, Germany.

Acquisition of the Corrugated Board Plant in Lugaro d'Erba, Italy.

2019

Acquisition of the REKA Corrugated Board Plant in Kitzingen, Germany.

2021

The world's most powerful paper machine PM5 for corrugated case material went into operation in Aalen, with an annual capacity of 750,000t and a working width of 10.9m. The paper mill in Aalen features a new power plant as well as a new wastewater treatment plant that incorporates the latest technology, a state-of-the-art new roll storage warehouse was also commissioned.

2022

The company is celebrating its 150th anniversary with innovative investments in all divisions and with the entry of Dr. Marina Palm, the 5th generation, into the traditional family business. Acquisition of the corrugated board plant OL Pack in Spino D'Adda, Italy.

2024

Acquisition of the corrugated board plant John Hargreaves (Collyhurst and Stalybridge) Ltd. in UK.

2025

Acquisition of five corrugated packaging plants in France, Spain and Portugal:

- Palm Packaging Cabourg SAS (north-west France/Normandy)

- Palm Packaging Mortagne SAS (north-west France/Normandy)

- Palm Packaging Saint-Amand SAS (north-west France/Normandy)

- Palm Packaging Bilbao S.L.U. (north-west Spain/Basque region)

- Palm Packaging Ovar S.A. (north of Portugal near Porto)

PALM strengthens its packaging division through a joint venture in the Czech Republic with a 50% stake in Power Packaging s.r.o..